Custom Sensors for Challenging Applications (Part 1)

April 01 2021

Mass production of sensors and monitoring solutions for Medical and Energy applications has been at the forefront of the growth at FISO since our spin-off from Canada’s National Optics Institute over 25 years ago. Investments in automated assembly and testing have increased our production capabilities such that our customers can depend on us to deliver sensors in high volume, on-time, with repeatable high quality.

In contrast, but very much complementary to our core value of innovation, we are also producing unique sensors for other harsh environments and challenging applications spanning several diverse market segments. These other markets include R&D Laboratories, Defense, Aerospace, Life Sciences, Structural Health Monitoring (SHM), and Industrial Process Control. Due to their small size, being intrinsically safe due to their non-sparking and non-short-circuit nature, plus having complete immunity to RF/EMI, our fiber-optic sensors are employed in applications such as:

- Automotive engine and battery testing

- Aerodynamic testing of high-speed trains

- Blast testing in human safety studies

- Cryogenic-use displacement monitoring

- Microwave-assisted drying processes

- Oil concentration ratio measurement

- Microwave-assisted chemistry

- Reservoir water level monitoring

- Preclinical small animal physiology

- Thermal monitoring during manufacturing and type testing of electronic devices

The options and specifications for standard configurations of our fiber-optic sensors are compiled in the datasheets below:

However, if you need something slightly different than what is shown in the datasheets… Please ask us!

For example, are the FOP-M pressure sensors or FOT-L temperature sensors seemingly too large?

Did you know that our sensors marketed for medical OEM applications can be used for non-medical applications?

Review the catalogs located on our Medical website pages in this case and let us know if one of those sensors is closer to what is needed in your application.

What can be customized?

To meet the requirements of the specific application and installation constraints, there are several attributes of the sensor that can be customized. Referring to the figure below, the main customizable elements of the sensor are the cable/jacket type, cable lengths, and tip protection.

While the optical transducer element is generally available in the multiple designs that FISO has mass-produced and the connectors are made to match the reading modules, the other elements can be customized to a great extent.

RED-LINE IT!

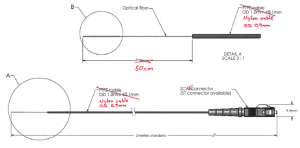

To most quickly communicate the customization requested, take the datasheet drawing and mark it up to show the desired dimensions of each section of the sensor. We refer to this as red-lining an existing drawing, and below are a few examples to see how easy this can be!

Example of a red-lined FOS-N strain sensor drawing

Example of a red-lined FOP pressure sensor drawing

Cable types in FISO’s repertoire include (i) 1.0mm & 1.7mm PTFE, (ii) 3mm armored, (iii) 3mm Polyurethane with Kevlar, (iv) 3mm spiral wrapped PTFE, (v) 3mm PVC, (vi) 0.9mm Nylon, (vii) 0.3 & 0.6mm polyimide tubing, and (viii) 155um polyimide coated fiber.

The most common tip designs include: (i) 0.3mm & 0.6mm polyimide sheathed, (ii) 0.3mm stainless steel sheathed, (iii) 152mm stainless steel tube with NPT male connector, (iv) no added parts, which we call “bare” in our literature, and (v) bare type with a centering ring behind.

Our product specialists can advise which cable types and tip protections are most suitable for your application.

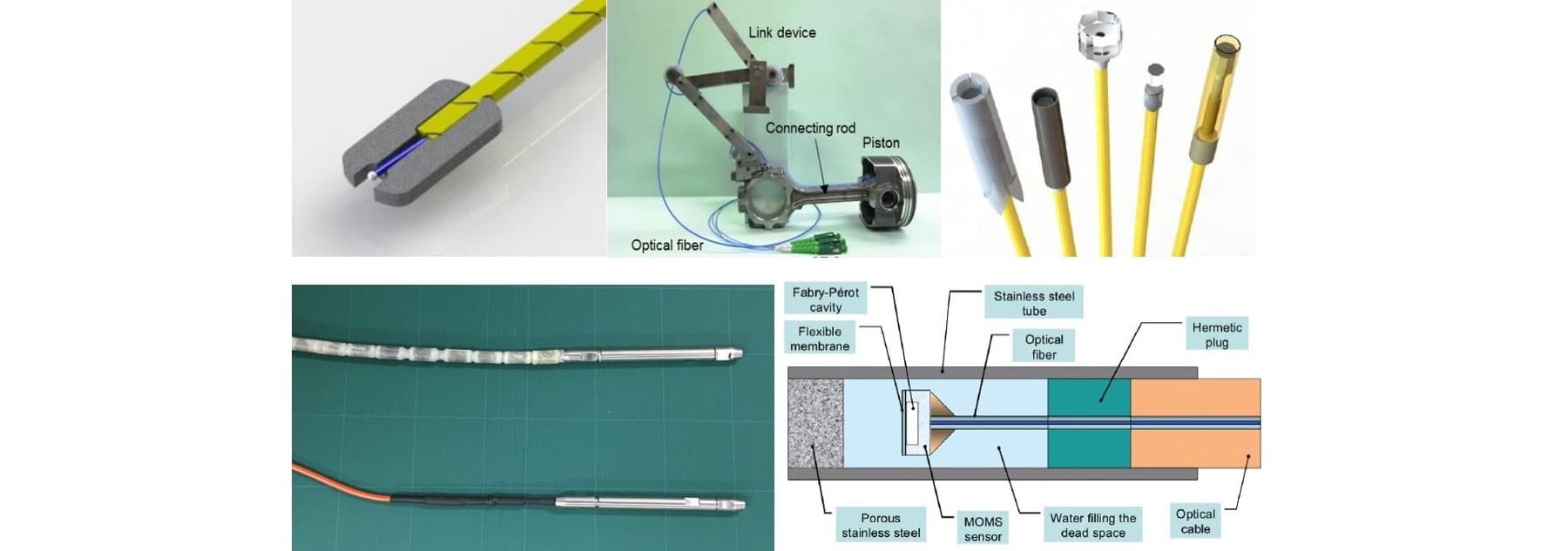

The customizations described above are simple modifications and represent just the beginning of what is possible. More elaborate sensor housings, multi-fiber bundles, and mechanical systems can also be designed by the engineers at FISO.

Do you have a challenging application where fiber optic sensors could make the difference?

We’d be happy to advise a custom solution.

Please contact us at info@fiso.com