Custom Sensors for Challenging Applications : Three Case Studies (Part II)

March 18 2021

In a previous article, we highlighted FISO’s ability to provide custom sensors for challenging applications. Customization of cable type, cable lengths, and tip protection was described in detail. The concept of red-lining drawings was also identified as the simplest way to communicate new requirements to FISO.

What if you are looking for something completely different?

There are hundreds of applications of fiber-optic sensors, and the design and installation constraints in many cases are unique. If you have a product idea that would add value to your particular application, please ask!

For example, a sensor’s tip design for ease of installation and maximizing long-term operation has many design possibilities. Since we have often been inspired by the requirements from our customers in this regard, a series of case studies will be illustrated here to bring to light some of those possibilities.

Case Study 1: Stator temperature monitoring in a large hydropower plant

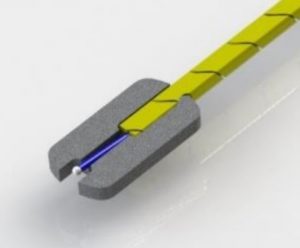

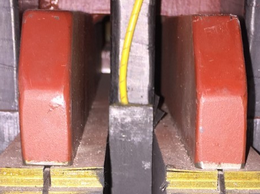

For installation into the spacers of the windings within a power transformer, FISO’s EasyDisk™ is the ideal tip design. For this case, the ability of the EasyDisk™ to snap into place and be in direct contact with the target surface were two key abilities that the operator of this power plant wanted to retain. However, the 18.55mm diameter of the EasyDisk™ was just too large. Could we design a new disk to snap into the available spaces on the stator for this new monitoring application?

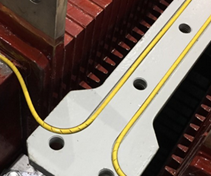

Solution: Slim EasyDisk™

The tip of this precisely machined slimmer version could be snapped into the machined grooves of the stator and robustly positioned at the measurement points of interest. The cables could also be kept within the grooves in most of the installation, and remain well protected within the large metal structure.

Besides slimmer disks, FISO can also offer slightly smaller circular disks, or thicker disks (3mm being most common).

On top of a custom temperature sensor, FISO has also supplied high-temperature extension cables for these kinds of projects. Custom solutions from FISO can extend further than just the sensors, and we can advise on other aspects of the installation. Fiber-optic feedthroughs, patch panels, panel housings, and monitor enclosures are examples of other products that FISO can provide for a monitoring project.

Case Study 2: Reservoir water level monitoring

Outside a growing and thriving Asian city, exists a large reservoir system that holds the freshwater for millions of people. The amount of water the reservoir held at any one time could be calculated by measuring water depth at various locations manually using extremely long steel rods. In the past, this work required personnel to operate and interpret. The regional water utility wanted to modernize this method of monitoring and move to automated, real-time measurements, with the side benefit of removing the chance of human error that had cropped up in the past. Unfortunately, the existing holes in which the rods were inserted to measure water level were extremely narrow. Could we design housing for a fiber-optic sensor that could fit inside the small holes and measure pore pressure?

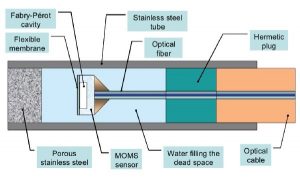

Solution: FOP Micro Piezometer

Large sensors were not feasible and so FISO’s 0.55mm diameter FOP-MIV pressure sensor was packaged inside a stainless steel casing for insertion at the base of the water columns. A porous stainless steel filter was added to keep silt and dirt outside of the dead space within the SS tube, but allow water to enter rapidly. At 4.8mm diameter, it was significantly smaller than other existing piezometers, based on various electrical sensor technologies, as the figure below right illustrates.

The fiber-optic cables used in these small piezometers have the additional benefit that the cable does not attract lightning like long electrical cables might. Therefore, fiber-optic piezometers can be used at locations where this benefit is well appreciated, such as at Tailings Dam sites.

Case Study 3: Pre-clinical small animal physiology pressure monitoring

FISO’s bare FOP pressure sensors had been used for years in pre-clinical small animal physiology studies by clever researchers who saw the advantages of the micro-optic sensing technology. Unfortunately, the pioneers of this application often experienced breakage of the Fabry-Perot sensor’s flexible membrane either during operation or subsequent cleaning. How could we make the sensor more robust for repeated usage by doctors and researchers?

Solution: The FISO Catheter

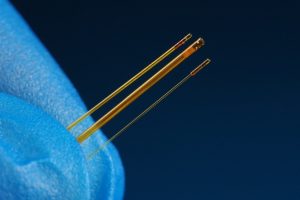

The bare FOP sensor is covered by a rigid polyimide sheath, recessed slightly at the distal end, with a small amount of gel applied to cover and thus protect the sensor membrane. The gel also allows for ease of cleaning and sterilization, as it restricts blood from entering into the tube and becoming lodged behind the MOMS (micro-optic mechanical structure) which is then very difficult to clean. A few different polyimide tube variants are provided as the figure below illustrates, optimized for the different sizes of the test subjects.

If a custom product results in widespread adoption, these custom products can become standard products later. The FISO Catheter is an example of a custom sensor that became standardized. Consult FISO’s Life Sciences catalog to review the standard models of the FISO Catheter that are offered today.

Interestingly, from this standard product offering, we have continued to customize. Researchers asked if we could make the tip radio-opaque and thus visible during certain procedures. Our engineers thought, why not use miniature metal tubing instead of the polyimide tubing, which would also act as a radio-opaque marker band?

As the photo above demonstrates, metal tubes can be made sufficiently small to be used in many different small-animal physiology studies. The metal tube allows the researcher to precisely know where the catheter tip is located within the test subject under fluoroscopy.

Other Case Studies

The three case studies presented in this blog represent just some of the higher-level customizations that are possible. In future blogs, we will present more case studies where new application-specific solutions are engineered via collaboration with our customers.

Do you have a challenging application where fiber optic sensors could make the difference?

We’d be happy to advise a custom solution.

Please contact us at info@fiso.com